One system. Endless possibilities.

PFM/PLF

Modular Filling System for Bottles, Jars, Jugs, Cups, and Trays

Product: Liquid, Paste

Output: Up to 10 Filling Heads

From thick sauces and dressings to powders, chemicals, and beverages, the Container Packaging System is built for adaptability. Designed to handle a wide range of container formats—including bottles, jars, jugs, cups, and trays – this system delivers precise, repeatable performance across diverse applications and packaging materials.

Packline offers rotary and in-line configurations that combine filling, sealing, capping, labeling, and more – streamlining your production line without sacrificing control.

Perfect for:

- Sauces

- Dressings

- Juice & Beverages

- Powders & Dry Goods

- Chemicals & Detergents

- Dairy

- Puddings

- Ready Meals

Specifications

Modular Filling & Packaging Performance

This system is available in rotary and in-line configurations, supporting automatic or semi-automatic operation. Whether filling a single bottle or sealing multi-component trays, the system ensures accurate dosing, hygienic handling, and clean container transfer at every stage.

Packaging & Filling Options

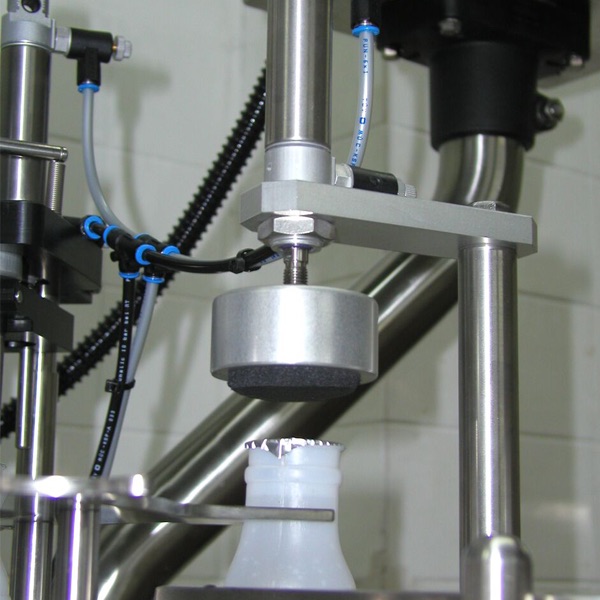

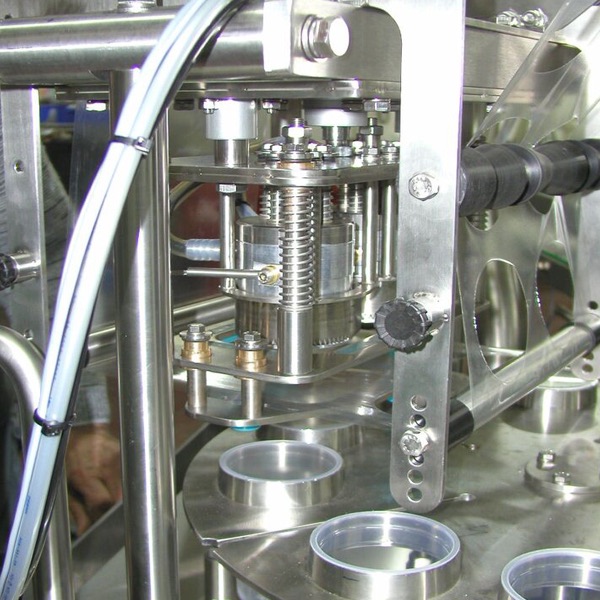

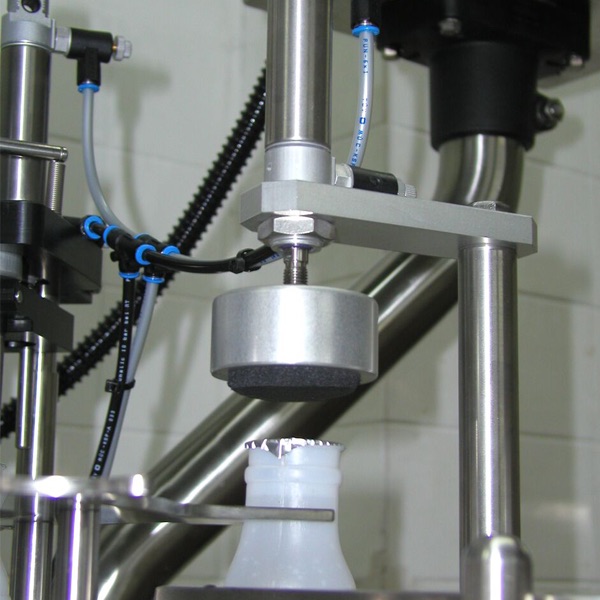

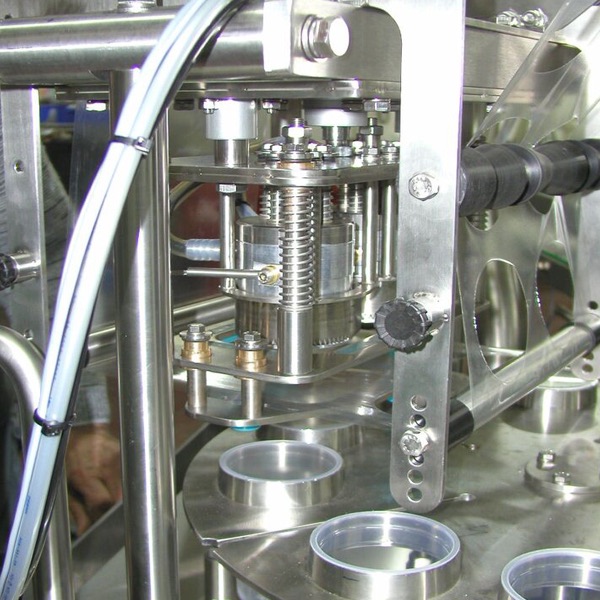

- PFM Rotary Bottling Machine – Pneumatic assemblies and mechanical platform, ideal for liquids and viscous products

- PLF Platform – Forms and cuts membranes from roll stock; fills and seals up to 20 oz containers

Supports a wide range of container formats – Bottles, jars, jugs, trays, and cups - Dual or multi-head fillers available – Fill multiple containers or dual-fill within a single container

- Quick-change adjustments – For varying container sizes and closure types

Integrated Systems for Smarter Filling

- PLC Control System – Regulates fill quantities with precision

- Clean-in-Place (CIP) – Streamlines sanitation between product runs

- Suck-Back & Cut-Off Nozzles – Reduces drips, ensures clean fills

- Weight Checking System – Real-time feedback to adjust fill accuracy

- Photoelectric Sensors – Ensure proper bottle alignment prior to filling

- Rotary Table & Conveyor Integration – Smooth infeed and discharge

- Labeling Station – For self-adhesive label application

- MAP System – Modified atmosphere for extended shelf life

- Coding Devices – For traceability and brand requirements

Container Closing Systems

Capping, sealing, and lidding are handled automatically based on your container and product needs. From simple pressure caps to heat-sealed membranes, every closure is designed for integrity and speed.

- Pre-Die Cut Lid Sealing (Aluminum or Film)

- Membrane Cutting & Application from Roll

- Snap-On or Screw-On Cap Application

- Discharge Conveyor & Rotary Table Options

- Code Printing on Lid or Bottle

Materials

We source high-quality, performance-tested materials that integrate effortlessly with equipment.

Packaging

Experience custom machinery solutions today.

Packline’s Linear Packaging System is built for growth. Whether you're scaling up production or improving the efficiency of your line, we’ll help you configure the right fillers, sealers, and automation features to fit your goals.